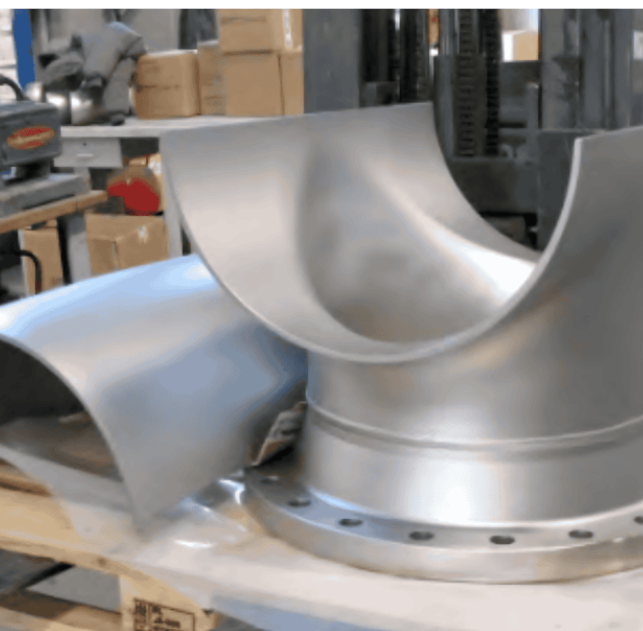

Split Tees

The Perils of Subpar Split Tees

Inferior Split Tees can lead to catastrophic consequences:

Operational Paralysis: Imagine a pipeline shutdown for a simple modification, costing millions in lost production. The revenue hemorrhage, contract penalties, and market share erosion - all from the absence of a quality Split Tees.

Safety Nightmare: Picture a rushed pipeline depressurization leading to a catastrophic failure. The potential loss of life, environmental devastation, and regulatory crackdown - all stemming from the inability to perform safe hot tapping.

Repair Roulette: Consider the risks of attempting emergency repairs with inadequate equipment. The compromised pipeline integrity, potential leaks, and prolonged downtime - all due to the lack of a reliable Split Tees solution.

Modification Mayhem: Visualize the chaos of pipeline expansion projects grinding to a halt due to incompatible fittings. The project delays, cost overruns, and stakeholder disappointment - all traceable to inferior Split Tees design.

Hotline Order:

Mon - Fri: 07AM - 06PM

(+965) 7492-4277

Size Range | Class/ Rating |

|---|---|

Size 4" to 24" | #150 to #1500 CL. |

Size 4" to 36" | #150 to #900 CL. |

Size 4" to 42" | #150 to #600 CL. |

Service | Design Stardard & Design Factor |

Hydro carbon, Oil & Gas and Water | ASME B31.4, B31.8 & 31.3 for Tee and Design Factor .4, .5, .6, .72 |

Material & dimension Standard | Dimension Stardard |

MOC ASTM A234 GR. WPB, ASTM A860/MSS-SP-75 GR. WPHY 42/ 46/52/ 56/60/ 65/70 & WPHY 80 For Tee and ASTM A105 & A694 for Flange. | As per VIVIAL Standard or Client approved drawing. |

Add your review

Your email address will not be published. Required fields are marked *

Please login to write review!

Looks like there are no reviews yet.