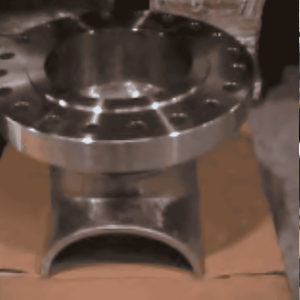

Barred Tees

The Dangers of Subpar Barred Tees

Inferior Barred Tees can lead to catastrophic consequences.

- Imagine a pig veering off course into a branch line, requiring costly retrieval operations. The production downtime, equipment damage, and emergency interventions - all from one inadequate Barred Tees.

- Picture a high-pressure pig launcher malfunction due to a poorly designed Barred Tees. The potential injuries, equipment damage, and regulatory investigations - all stemming from a single flawed component.

- Consider the cumulative impact of frequent pigging interruptions due to substandard Barred Tees. The reduced cleaning effectiveness, increased operational costs, and compromised pipeline integrity - all due to overlooking this critical component.

- Visualize the nightmare of repeated pipeline shutdowns for pig retrieval from branch lines. The operational disruptions, safety risks, and skyrocketing maintenance costs - all traceable to inferior Barred Tees design.

Hotline Order:

Mon - Fri: 07AM - 06PM

(+965) 7492-4277

Size Range | Class/ Rating |

|---|---|

Size 4" to 24" | #150 to #1500 CL. |

Size 4" to 36" | #150 to #900 CL. |

Size 4" to 42" | #150 to #600 CL. |

Service | Design Stardard & Design Factor |

Hydro carbon, Oil & Gas and Water | ASME B31.4, B31.8 & 31.3 for Tee and Design Factor .4, .5, .6, .72 |

Material & dimension Standard | Dimension Stardard |

MOC ASTM A234 GR. WPB, ASTM A860/MSS-SP-75 GR. WPHY 46, WPHY 46, WPHY 52, WPHY-56, WPHY 60, WPHY 65, WPHY 70 & WPHY 80 For Tee and ASTM A516 GR. 60/70 for Bar. | ASME B16.9, MSS SP 75, B16.25 for Tee and bars as per Internal or Client approved drawing. |

Add your review

Your email address will not be published. Required fields are marked *

Please login to write review!

Looks like there are no reviews yet.